The Moving Bed Biofilm Reactor (MBBR)

The Moving Bed Biofilm Reactor (MBBR), originally invented at the Norwegian University of Science and Technology, incorporates the combined benefits of Activated Sludge and Attached Growth wastewater treatment processes. RH2O® North America adopted and professionally tailored MBBR technology to guarantee performance in the unique Canadian climate and meet specific regulatory and project requirements.

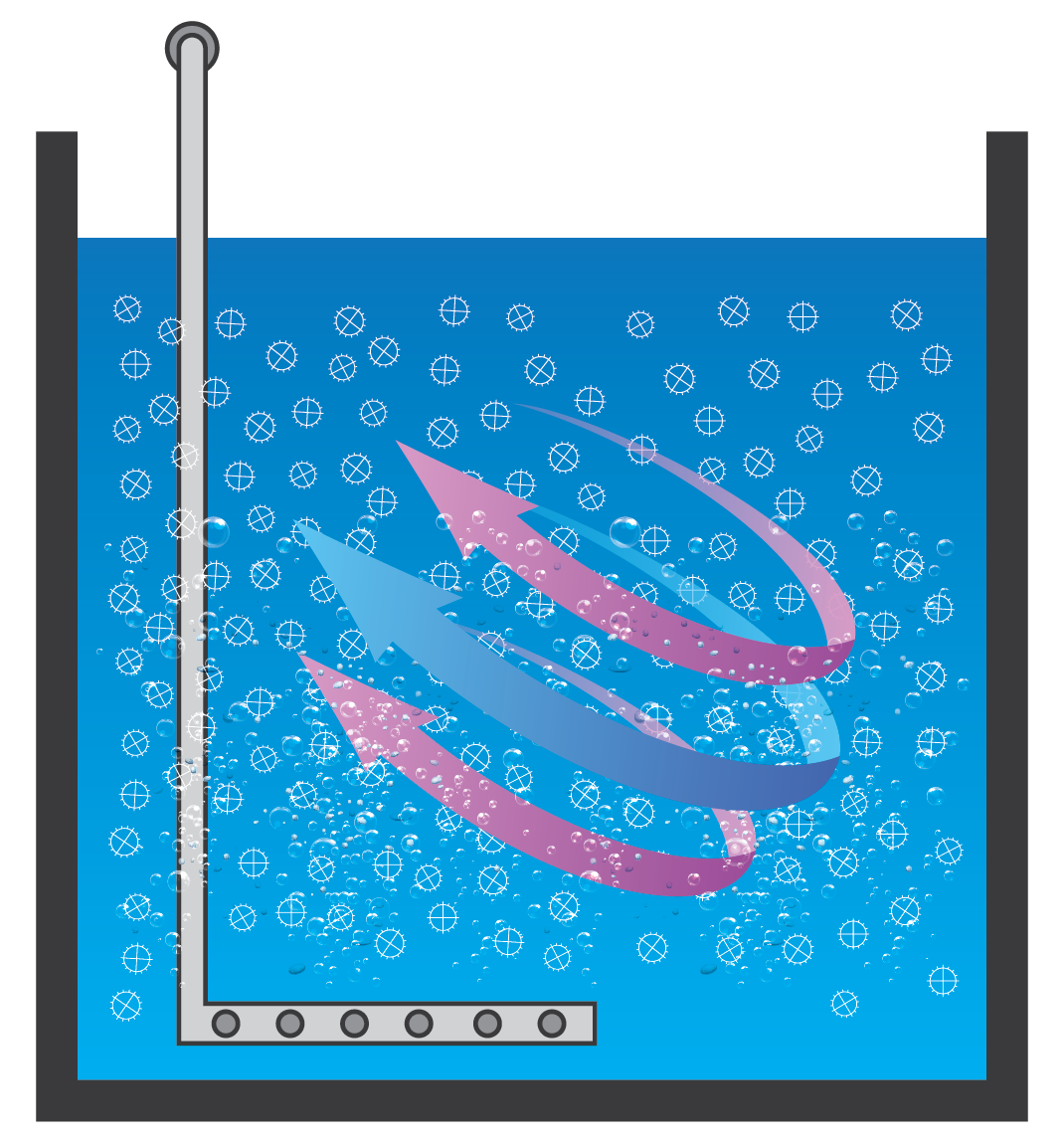

Self-cleaning media at the core of the process

Applications for RH2O®

Campgrounds, RV and Mobile Home Communities

Our systems are designed to meets the most stringent effluent requirements for:

Nitrification

DeNitrification

Phosphorus Removal

Disinfection / Wastewater Reuse

Retrofit / Upgrade Other

Treatment Systems

RH2O® Advantages

RH2O® Design Software provides process simulation and proactive troubleshooting to ensure each project performs to the most stringent of effluent requirements.

Self-cleaning media doesn’t clog or need replacement and is resilient against hydraulic and organic shock loads.

Our systems can be designed as a complete stand-alone process or may be retrofitted/upgraded to assist other technologies meet performance requirements.

RH2O® Design Software provides process simulation and proactive troubleshooting to ensure each project performs to the most stringent of effluent requirements.

Self-cleaning media doesn’t clog or need replacement and is resilient against hydraulic and organic shock loads.

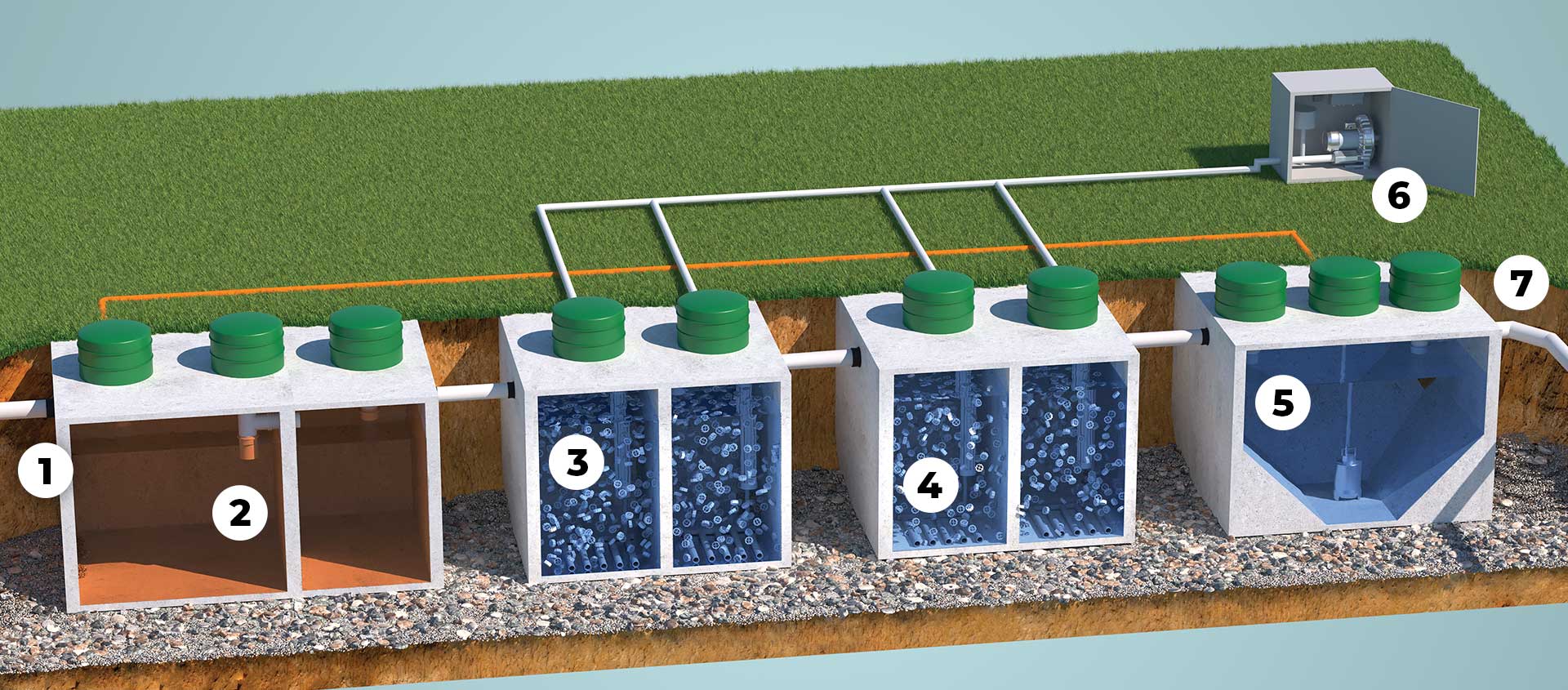

Commercial Wastewater System

1. Inlet

2. Primary Clarification

3. Biological Treatment

4. Biological Treatment

1. Inlet

2. Primary Clarification

3. Biological Treatment

4. Biological Treatment

5. Final Clarification

6. Control Unit

7. System Discharge

5. Final Clarification

6. Control Unit

7. System Discharge

Designed and Built for Minimal Maintenance

Our systems are designed for ease of operation and maintenance. The automated control system provides instant notification to the maintenance provider and allows remote connect to the control panel via wireless connection. The self-cleaning media reduces the amount of maintenance visits and the control system provides assurance of 24/7 round the clock operation.

Wastewater

Resources

Wastewater

Resources

Advanced Wastewater Treatment Solutions Brochure

Contact Us

As a leader in water treatment, RH2O® can help you reap the benefits of innovative water management, saving you money and reducing your environmental impact.

For information or a project quotation, please contact:

RH2O® North America Inc.

65 Massey Road, Suite C

Guelph ON N1H 7M6

PHONE: (519) 648-3475

FAX: (519) 856-0759

EMAIL: Rh2o@waterloo-biofilter.com

FOR EMERGENCY AFTER HOURS SERVICE:

Call (519) 648-3475

Press #3 for Services

Press #2 for After Hours Service

Legal | Privacy Policy | Website by REES + STAGER

Legal | Privacy Policy | Website by REES + STAGER

Legal | Privacy Policy | Website by REES + STAGER